Working Principle and Operation Manual of Servo Electric Press

Precision CNC servo electronic press is referred to as servo press or electronic press. Its working principle is that the servo motor drives the high-precision ball screw for precision pressure assembly. It can realize the closed-loop control of the whole process of pressing force and pressing depth in the pressure assembly operation, so as to achieve the precision pressing of on-line quality management.

The function of an electric cylinder servo press is the same as that of a pneumatic press and hydraulic press. They are all applied to the lifting, pushing, and stamping of the objects. The difference is that servo presses do not require compressors or hydraulic stations. As long as there is a power supply, it can be driven and used. It adopts electric cylinders (also known as electric linear actuators), which have the characteristics of high efficiency, low noise, cleanliness, and zero pollution. In addition, electric cylinders can achieve precise position, and are the better alternative to air and hydraulic cylinders.

The electric cylinder servo press mainly consists of the servo motor, aluminum casing, motion drive device (usually a ball screw), and position feedback device. The basic principle is that the human-machine intelligence sends commands to the servo driver, and the servo motor works under these commands, driving the ball screw to rotate through the transmission mechanism. Driven by the rotational torque of the ball screw, it moves in a reciprocating linear motion with the piston rod. The position feedback device detects the position of the electric cylinder piston rod in real-time at the screw rod, thereby achieving precise control of linear displacement.

1. The displacement repetition accuracy is 0.01mm.

2. The pressure repetition accuracy is 1% F.S.

3. It can realize single stroke six stages speed with precision pressfitting.

4. Online press fitting can judge the quality of products.

5. The pressing process is displayed in real time in theform of curve.

6. Three press fit modes are available.

7. 100 sets of press fitting procedures can be set.

8. Press fit data can be stored and extracted.

1. Fast forward: approaching the workpiece quickly

2. Control test: testing from no-load to load

3. Press fit: workpiece press in

4. Buffer: decelerate before the end of press fitting

5. Pressure maintaining: press fitting end position stays

6. Return: return to work origin quickly

1. Constant press fitting speed, set precise position and stop.

2. Constant press fitting speed, set precise pressure and stop.

3. Constant press fitting speed, set accurate displacement andstop.

1. It realizes the full closed-loop control of precision pressure and displacement, andhas the characteristics of high precision.

2. Compared with the traditional pneumatic, the energy-saving effect of the hydraulic press is more than 80%. It is more environmentally friendly, safe and can meet the equipment use requirements in the dust-free workshop.

3. The whole process curve of pressing force and displacement can be displayed on LCD and touch screen. The whole process control can automatically determinewhether the product is qualified at any stage of operation. The machine removes defective products 100% in real time, so as to realize online quality management.

4. The pressing force, pressing depth, pressure speed and pressure holding time can all be input on the operation panel, and the interface operation is simple.

5. Up to 100 sets of press fitting programs can be customized, stored and called. Three modes are available to meet the different process requirements.

6. Through the USB interface, the press fitting data can be stored in the USB flashdisk to ensure the traceability of product processing data and facilitate production quality control.

7. The machine has precise pressure and displacement control functions, and there is no need to add hard limit on the tooling. Processing products of different specifications only needs to call different press fitting programs, so it can easily realize one machine multi-purpose and flexible assembly line.

The press fitting machine is driven by an imported servo motor electric cylinder, and controlled by an imported high-speed PLC. It is controlled by the human-machine dialogue of the configuration function touch screen and the participation of force sensors, thereby implementing high-precision pressing operations.

Press fitting mode

1. Constant press fitting speed, set precise position and stop.

2. Constant press fitting speed, set precise pressure and stop.

3. Constant press fitting speed, set accurate displacement and stop.

Quality judgment function

It has online quality inspection function to ensure product quality. Up to 5 detection sampling points can be freely set within a certain range.

Parameter report storage function

It is connected through the USB interface, and the results of pressing operation data can be stored in an orderly manner on a USB drive. Therefore, it can ensure the traceability of product data and effectively control the production quality.

Touch control screen

The perfect combination of large screen high color LCD touch screen and configuration software provides friendly human-machine dialogue function.

Self-diagnosis function

When a device malfunctions, the electronic press can display an error message and prompt for a solution, making it easy to quickly identify and solve the problem.

Multifunctional I/O communication interface

It can communicate with external devices through this interface, facilitating fully automated integration.

Environmental protection, energy conservation, and safety

It drives electronic pressure through an AC servo motor, providing a clean working environment. Compared with pneumatic and hydraulic equipment, servo press machines save 80% energy. In order to ensure safety, electronic press is equipped with safety protection circuits.

Emergency stop

In any state (except for the set state), it is used as an emergency stop. In case of an emergency, press the emergency stop button and the device will be in a paused state. The device cannot proceed to the next action and can only operate normally by manually rotating the button counterclockwise to release it.

System startup

After the external power supply is turned on (the main switch is closed), press this button to turn on the power supply of the equipment control system. When not using this device for a long time, be sure to cut off the main circuit power switch (circuit breaker main switch).

Reset switch

If the device is pressed during operation, it will slowly reset to the working origin.

Tricolor lamp

It displays the current working status of the device in real time.

1. Green light flashing: working

2. Yellow light flashing: standby

3. Red light flashing: abnormal alarm

Buzzer

When an abnormal situation occurs during the operation of the device, the buzzer will emit a short prompt sound of “Beep! Beep! Beep! ”.

USB slot

Insert a USB drive (less than 16GB) into the USB slot, and all press fitting data in the touch screen can be exported.

I/O interface (optional)

It can be used online with external devices or fixture devices.

Touch screen

It adopts the touch type configuration function display screen, which can set system and program parameters, display the current device status, and other functions.

①Perimeter inspection

Before turning on the machine, check whether there is any obstacle within the effective stroke of the lower end of the pressure pusher.

②Power connection

Turn on the external power supply and put the external circuit breaker and the circuit breaker in the electrical box in ON state.

③System start

Press the “System Start” button. The power is on, and the system is turned on.

④Device reset

After entering the operating system, press “Click to Enter” on the screen, the equipment will enter the initialization state, and the electric cylinder will be reset to the factory origin position slowly.

⑤Operation

After initialization, the device enters the standby mode. After setting the relevant production parameters, press the double “Start” button to enter the operating state of the equipment.

Startup screen

Turn on the “System Start” switch of the device, and power on the device and operating system. After the touch screen self check is completed, it will automatically enter this screen.

Press “Click to Enter” in the screen, and the system will enter the “Operation Interface” screen.

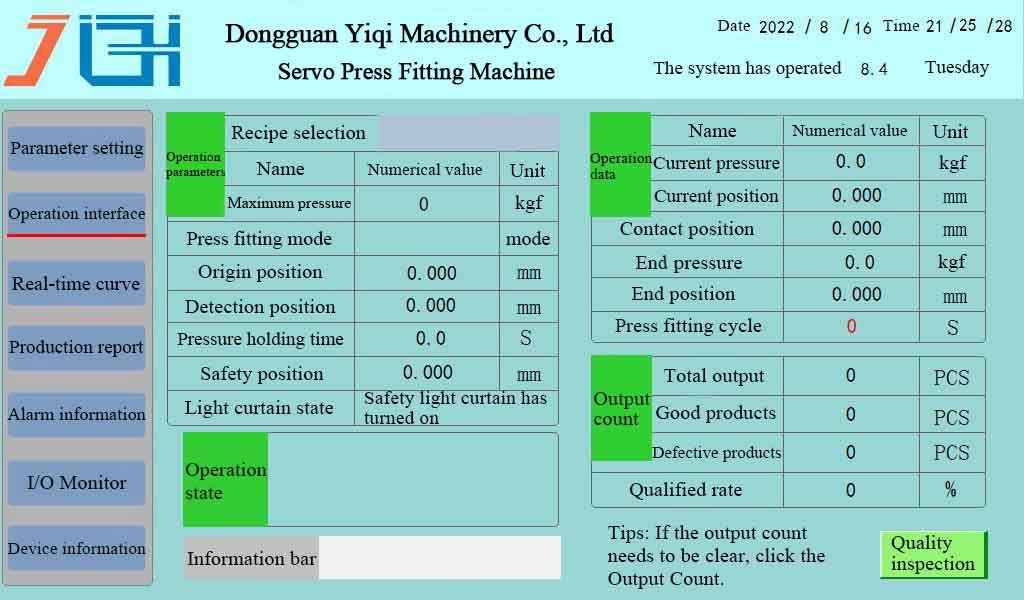

Operation interface

The main functions of this interface are divided into six parts:

1. Operating parameters 2. Operating state 3. Operating data 4. Output information

5. Information bar 6. Quality inspection

Operating parameters: Display some operation parameters related to equipment action (the same as the data in parameter setting).

Operating state: Display the current equipment operation status, some equipment error messages prompt and product judgment results.

Operating data: Display the real-time data during the current equipment operation.

Output information: Display the production quantity of products produced by the equipment. It can automatically turn on or off the statistics function of good and bad products and yield rate according to the parameter settings. If it is required to clear the counting quantity, click the “Output Information”.

Alarm bar: Display equipment abnormal operation or fault alarm prompt.

Quality inspection: This equipment provides up to 5 detection points: upper limit of detection pressure, lower limit of detection, actual value of detection and detection results. It is used to detect, extract and judge the position of detection points and pressure data in the process of press fitting.

Recipe editing

Click to enter “Recipe Name”, and the keyboard will automatically pop up to edit the name of the recipe. (Combination of letters and numbers)

The equipment has three working modes: target location mode, target pressure mode and target displacement mode.

Target location mode: Maintain the pressure after the equipment operates to the set position, and return to the working origin when the pressure maintaining time is up.

Target pressure mode: Maintain the pressure after the equipment operates to the set pressure, and return to the working origin when the pressure maintaining time is up.

Target displacement mode: Maintain the pressure after the equipment operates to the set displacement, and return to the working origin when the pressure maintaining time is up.

Buffer deceleration: Buffer deceleration before the equipment operates to the pressure maintaining position.

Quality inspection parameter setting

This equipment provides up to 5 detection points. It is used to detect, extract and judge the position of detection points and pressure data in the process of press fitting. Click “detection point” to open or close the detection point.

The existing parameters can be saved in each parameter setting window.

Data export

This window can export historical data through USB flash disk. Insert the USB stick first, enter the name of the download folder after 10 seconds, then click download to export the data completely. It can be directly opened, edited or browsed through EXECL form on the computer.

Password modification

Click the “Password Window” on the left side of the “Parameter Setting” window. After entering the current password, the system will pop up the above screen, and it can modify the current password by prompting.

Attention: The above passwords must be kept in mind after modification, otherwise the system screen or functions with permission will not be accessible.

Quality inspection data

This window detects and captures the data of the set detection points during the press fitting process, and can switch with the “Quality Inspection Data” window in the “Operation Interface” window.

Detection point: If the font of a detection point turns red and flashes during press fitting, the detection point is not detected at this press fitting point. Please check whether the parameter setting is reasonable.

Detection value: Display the data captured in the set detection point.

If the background of the data frame is red, it is judged as NG. If the background of the data frame is green, it is judged as OK.

Real time alarm

This window can display the current equipment alarm information in real time.

Please get the corresponding solution to the alarm cancellation according to the lighted label prompt in the window.

Real time curve

This window can display the current product press fitting curve in real time.

The X axis coordinate is the pressure value. Enter the maximum displayed value of X axis in the data box window on the right of X axis. The curve can be zoomed in or out through the above settings.

The Y axis coordinate is a position value. Enter the Y axis in the upper and lower data frame windows of the Y axis.

It can set the curve position/pressure start and end points.

The number of curve judgments depends on the number of F1-F5 detection points.

Curve saving

After inserting the USB flash disk, clicking “Curve Saving” will automatically save the current page.

Production report

This window can view the historical press fitting data. If the “Quality Inspection Function” is not enabled, the press fitting data will not be recorded.

Control system I/O status

This window displays the real-time working status of I/O ports in the equipment control system in real time, and provides maintenance reference credentials for equipment maintenance personnel.

Technician formula transfer

Click to enter the “Recipe Name”, and the system will automatically pop up the password authority management window. Enter the correct password to enter the formula transfer window. The original factory password is “456”.

After entering the correct password, the following screen will pop up automatically.

Transfer the required formula parameters, and it will automatically return to the “Operation Interface”.

Device information

This window displays the basic specification information of the device.

This equipment is designed to save energy and reduce consumption, and has an automatic power off function.

If the equipment is not operated for a long time, the equipment will automatically power off.

Servo press is a press that uses the servo motors for control. It has a wide range of applications, including automobiles, motors, electronics, as well as household appliances and machinery. It is mainly used for component pressing in various industries. The selection of servo press series and types varies greatly among different industries. Therefore, the selection of servo press is also very important.

Main application areas of the equipment:

1. Automotive industry: engine component press fitting (cylinder head, cylinder liner, oil seal, etc.), steering gear componentpress fitting (gears, pins, etc.), transmission shaft component press fitting, gearbox component press fitting, brake disc component press fitting, etc.

2. Motor industry: micro motor component press fitting (spindle, shell, etc.), motor component press fitting (bearings, spindle, etc.).

3. Electronics industry: circuit board component pressfitting (plug-in, etc.), electronic component press fitting.

4. Home appliance industry: home appliance parts press fitting, home appliance parts riveting, etc.

5. Mechanical industry: mechanical component pressfitting, automated assembly, and life testing of vulnerable parts.

6. Other industries: other occasions that require precision CNC pressfittingdisplacement and pressing force.

YIqi Machinery

hydraulic press machine manufacturer

Social Media

Most Popular

IMD Heat Press Machine

Features and Applications of C Frame Hydraulic Press

Get In Touch

No matter what type of Hydraulic Presses you need, based on our rich experience, we can provide the most suitable scheme and design for the industry.