Features And Applications Of

C Frame Hydraulic Press

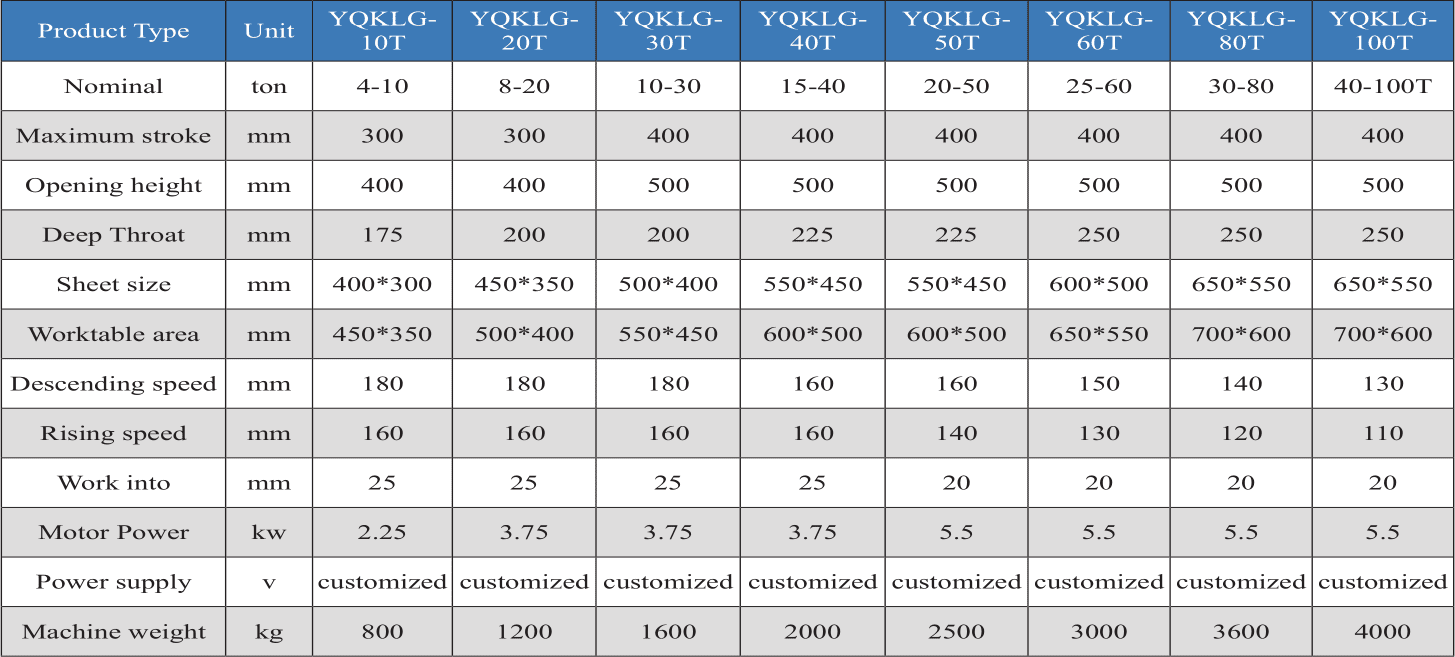

C frame hydraulic press, also known as single arm hydraulic press, is a multifunctional open structure hydraulic press. The most prominent advantage of C frame hydraulic press is its easy operation and the ability to approach the workpiece on three sides. It is easy to load and unload, and is convenient for the application of processes such as straightening shaft parts and bending and forming plates. This machine is suitable for bending, stamping, blanking, correction, flanging, pressing and other processes of metal parts. It can also be used for pressing and forming powder products, abrasive products, as well as plastic products and insulation materials. The pressure, stroke, worktable area, die head size, height of the worktable from the ground, and other parameters of the machine can be customized according to customer process requirements.

The C frame hydraulic press adopts a C type structure, which has a wide range of applications and universality. It is suitable for pressing plastic materials and powder products, calibration of shafts and other similar parts, press fitting of electrical components, process applications such as forming, blanking, stamping, and embossing. C frame hydraulic press can be operated by hand or foot, and the pressure can be adjusted arbitrarily within the specified range. It is easy to operate, flexible, and safe to use.

(30 ton floor type C frame hydraulic press)

1. The machine adopts an integrated welded open structure, which can keep the fuselage rigid enough and have convenient operation space.

2. The machine transmits energy with hydraulic power source, and adopts fast and slow speed oil cylinder. It descends rapidly and presses slowly. At the same time, it has flexible control and fast running speed with stable pressure and wide adjustment range. High efficiency and low energy consumption greatly improve the press fitting quality of products.

3. Imported high-quality hydraulic components and electrical components are adopted with stable performance and durability.

4. The operation of the machine is simple. The pressure, stroke and closing height can be adjusted according to the pressing process requirements.

5. The PLC control system is adopted. It uses two handed operation, including emergency stop and inching functions. Infrared safety light curtain protection device is optional, safe and efficient.

6. The opening height, stroke and worktable size of the press can be customized according to the process needs of customers.

7. Non standard design customization: intelligent equipment such as multi station rotary table device, cylinder jacking device, material receiving device, side cylinder sliding table expansion device. It can be equipped with cooling system, pressure maintaining function, pressure relay, force measuring display, PLC man-machine interface, etc.

The capacity and quality of hydraulic oil will affect the performance of the hydraulic system. Low liquid level and improper filtration can cause air pollution. After the oil filter has been used for a long time, The debris on the filter element will continue to accumulate. This will affect the filtration capacity and increase the flow resistance, resulting in an increase in oil temperature and fluid pollution. The leakage will further aggravate these two problems.

The quality of hydraulic oil has a great impact on the performance of the hydraulic system. The high-quality hydraulic oil can also extend the service life of the hydraulic device and improve the safety and stability of the power system. Some oils even provide anti-wear and anti-foam additives, which can effectively prevent wear and air pollution.

1. It is used for embossing, forming, shaping, and press fitting of metal or non-metal parts.

2. It is used for forming glasses, watches, electronic connectors, correcting and pressing motor rotors, stators, and shaft sleeves.

3. It has a good effect on the die-cutting process of high-density circuit boards and wiring.

4. It is particularly suitable for shaft sleeve pressing and can achieve automatic detection and alarm function, making the product’s qualification rate reach 100%.

5. It is widely used for punching, embossing, shaping, riveting, bending, shearing of various materials, as well as the pressing and assembly of various small components.

The C frame hydraulic press have strong versatility. It adds a pressure sensor on the hydraulic press, through the data collection and system processing composed of a microcomputer. It is converted into the pressing value for digital display. When exceeding the limit, sound and light alarms and shutdown signals are sent to achieve automatic control of the pressing force. The load display controller of the machine has clear display and accurate control. It has fast response, stable and reliable operation. Replacing different sensors and application software can be used for stamping equipment with different tonnage. The application of counters can enable each operator to know the total number and the number of failures. It adds two-handed buttons, and the operation of the machine is better. After adding two-handed button, the operation of the machine is better.

YIqi Machinery

hydraulic press machine manufacturer

Social Media

Most Popular

IMD Heat Press Machine

Features and Applications of C Frame Hydraulic Press

Get In Touch

No matter what type of Hydraulic Presses you need, based on our rich experience, we can provide the most suitable scheme and design for the industry.