Floor Hydraulic Press a kind of machine with liquid as the working medium, which uses liquid static pressure to transfer energy for realizing various processes. The principle is based on Pascal’s law.It is suitable for metal stamping, die casting cutting, silicone stamping, bearing press fitting and other processes.

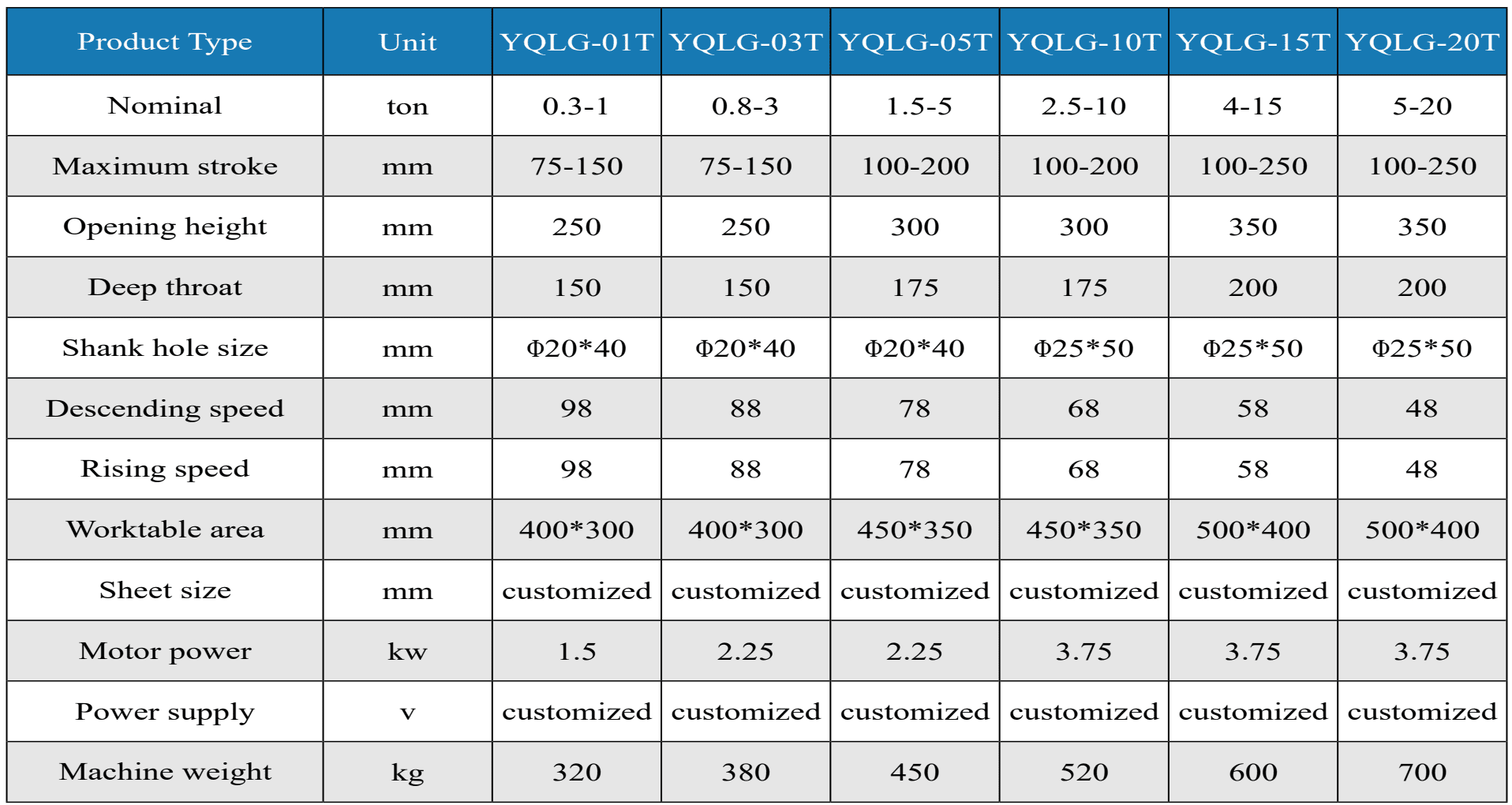

| Nominal | 1Ton/3Ton/5Ton/10Ton/15Ton/20Ton/more |

|---|---|

| Maximum opening height | 200mm/250mm/300mm/400mm/more |

| Minimum closing height | 0mm/50mm/100mm/150mm/more |

| Volltage | customized |

Floor Hydraulic Press a kind of machine with liquid as the working medium, which uses liquid static pressure to transfer energy for realizing various processes. The principle is based on Pascal’s law.It is suitable for metal stamping, die casting cutting, silicone stamping, bearing press fitting and other processes.

Scope of application:

1. This series of hydraulic press is suitable for press fitting, punching and riveting of

hardware parts.

2. It is used for punching, stamping, forming, shallow stretching, shaping and

pressure assembly of metal or non-metal parts, blanking of plastic plates, pressing of

powder products, etc.

3. It is especially suitable for stamping electronic insulation products, silicone

products, transformer shaping, motor assembly, axis and bearing pressing, etc.

Product features:

1. The machine adopts an integrated welded open structure, which can keep the

fuselage rigid enough and have convenient operation space.

2. The machine transmits energy with hydraulic power source and adopts double

pistons fast oil cylinder. It descends rapidly and presses slowly. At the same time, it

has flexible control and fast running speed with stable pressure and wide adjustment

range. High efficiency and low energy consumption greatly improve the press fitting

quality of products.

3. Imported high-quality hydraulic components and electrical components are

adopted with stable performance and durability.

4. The operation of the machine is simple. The pressure, stroke and closing height

can be adjusted according to the pressing process requirements.

5. PLC control system is adopted. It uses two handed operation, including emergency

stop and inching functions. Infrared safety light curtain protection device is optional,

safe and efficient.

6. The opening height, stroke and worktable size of the press can be customized

according to the process needs of customers.

7. Non standard design customization: intelligent equipments such as multi station

rotary table device, cylinder jacking device, material receiving device, side cylinder

sliding table expansion device. It can be equipped with cooling system, pressure

maintaining function, pressure relay, force measuring display, PLC man-machine

interface, etc.