Heat Press Machine/Hydraulic Hot Press Machine is a kind of machine with liquid as the working medium, which uses liquid static pressure to transfer energy for realizing various processes. A four post hydraulic presses is composed of four columns. The upper and lower beams form the frame of the hydraulic press, which is usually used to accomplish pressing processes and press molding processes.

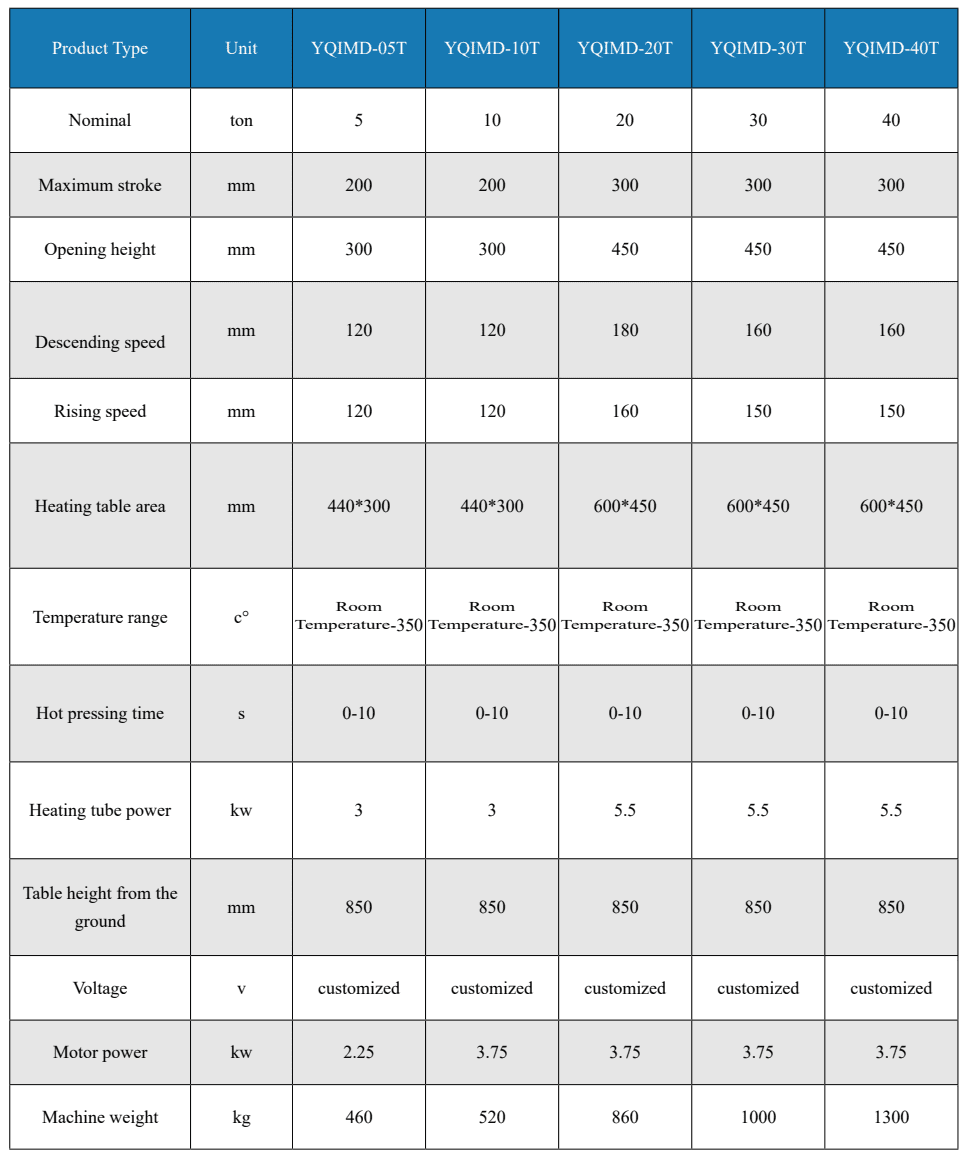

| Nominal | 05Ton/10Ton/20Ton/30Ton/40Ton/more |

|---|---|

| Maximum opening height | 300mm/400mm/500mm/600mm |

| Minimum closing height | 0mm/50mm/100mm/150mm/more |

| Volltage | customized |

Heat Press Machine/Hydraulic Hot Press Machine is a kind of machine with liquid as the working medium, which uses liquid static pressure to transfer energy for realizing various processes. A four post hydraulic presses is composed of four columns. The upper and lower beams form the frame of the hydraulic press, which is usually used to accomplish pressing processes and press molding processes.

Scope of application:

Home appliance industry: control trim panel of rice cooker, washing machine,

microwave oven, air conditioner, refrigerator, etc.

Electronics: shell and sign of mobile phone, tablet computer, calculator, electronic

notepad, camera, etc.

Automobile industry: dashboard, air conditioning panel, interior trim, lamp shell,

logo, etc.

Computer industry: keyboard, mouse, shell.

Communication industry: mobile phone keys, mobile phone lenses, mobile phone

color-shell, fixed telephone panels and windows lenses.

Other industries: medical devices, cosmetic boxes, decorative boxes, toys, sports and

entertainment leisure products, etc.

Product features:

1. The design of this machine takes safety production as the leading idea. On the

basis of ensuring the production process requirements, the design adopts a highly

sensitive Infrared safety grating to provide accurate safety protection function for

the operator, so as to improve the work efficiency and reduce the rate of defective

products.

2. Full automatic control is the greatest advantage of this machine. It is controlled

by Mitsubishi PLC and has a series of functions such as manual / automatic,

safety protection, mold anti-collision protection, automatic temperature control

and pressure protection. It is a powerful guarantee to improve product quality and

production efficiency.

3. The heating system adopts Japanese pid intelligent digital display temperature

controller.

4. Preheating and holding time can be preset according to different requirements of

products.

5. The heating element adopts far-infrared radiation heating tube, which has the

characteristics of fast response, high efficiency and energy saving.

6. 1-20 mpa liquid pressure is used as the power source instead of compressed air.

Because the compressibility of hydraulic pressure is almost zero, the stability of

speed and pressure is much higher than that of ordinary IMD forming machine. The

output of the machine is optional at 5-50tf (ton force).

7. The machine controls the voltage of the heating body (reduce its power supply

voltage when it is close to the set temperature to ensure that the heating tube is in a

long-term lighting state and prolong its service life). The displayed temperature and

the actual temperature are controlled within ±1℃.

8. IMD hot press forming machine can be used for forming and punching as long as

the mold is replaced.

9. IMD forming machine is suitable for all kinds of facial mask stereo forming and

three dimensional punching.