Electric Servo Press

servo press

Flexible control of crimping stroke and crimping force, realizing fast and flexible mixed-line production, effectively improving processing quality, reducing defective rate, and saving cost. Environmentally friendly and pollution-free, meeting the dual requirements of high efficiency and energy saving in the process, realizing intelligent manufacturing.

Join our 30,000+ happy customers

What we do

Let us change the way you think about technology.

Communicate details and confirm requirements

The engineer team to make the design of reasonable technical solutions.

Repeated testing of more than 5000 cycles and strict inspection before shipment.

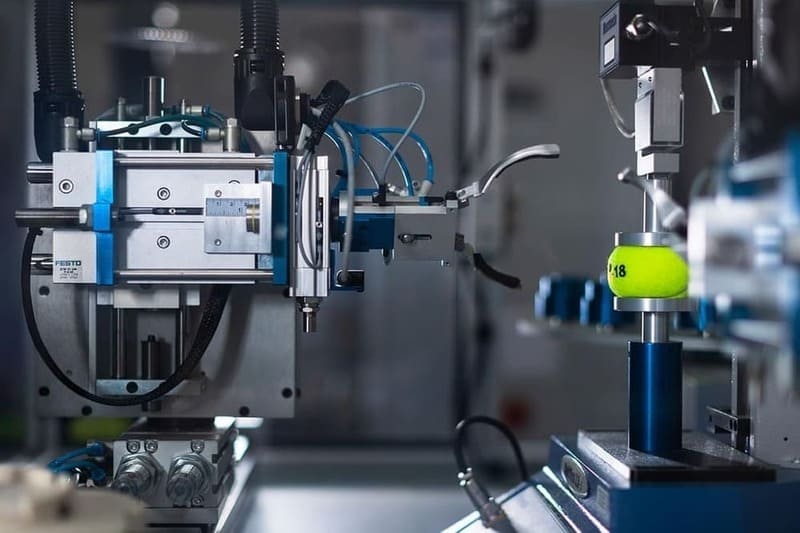

Machine Introduction

Introduction to electric servo presses

Versatility, short lead time, multi-functionality, customization

Divided into six parts:

1. Operating parameters;

2. Operating state;

3. Operating data;

4. Output information;

5. Information bar;

6. Quality inspection。

Password rights management window for easy protection of production parameters.

.jpg)

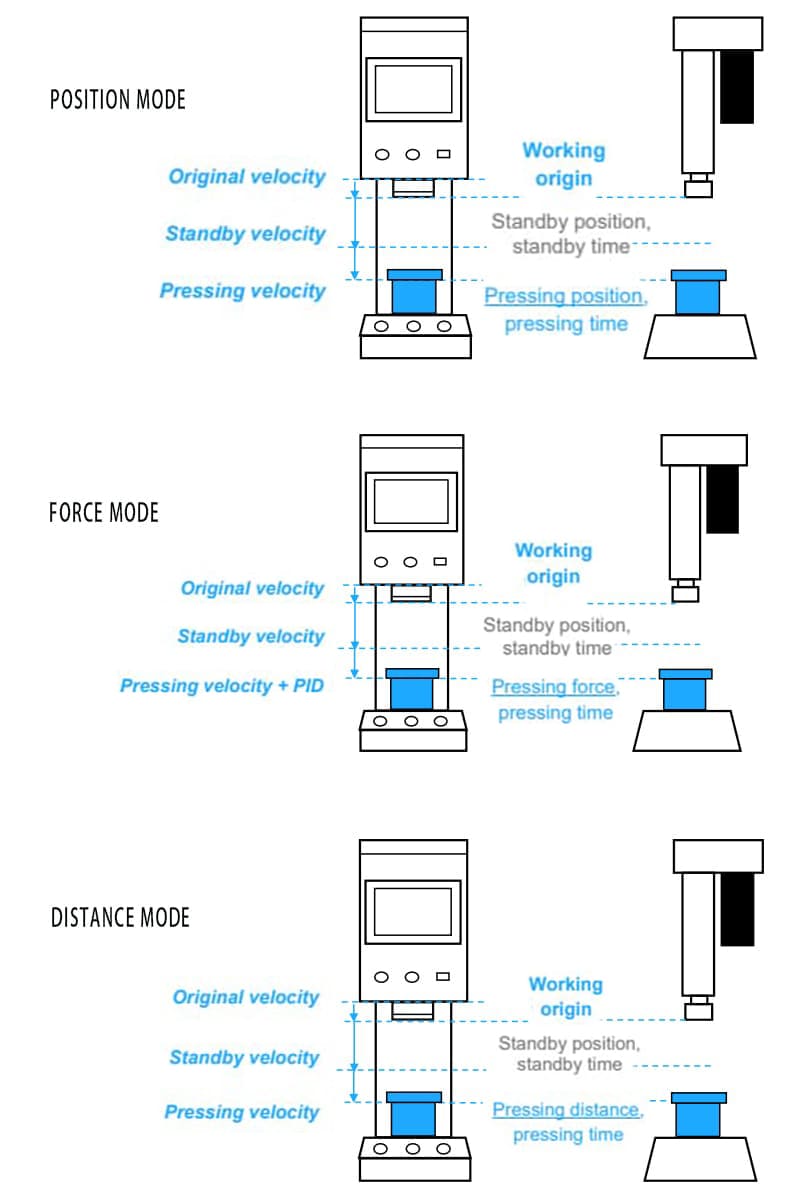

Integrated refined CNC settings, One-touch recalls Four operating modes:

1. Position mode;

2. Pressure mode;

3. Displacement mode;

4. I/O mode.

.jpg)

Detection point, used to detect and extract the location of the detection point and pressure data in the press-fitting process, and make a judgment

.jpg)

This window can display the current equipment alarm information in real-time. Please get the corresponding solution to the alarm cancellation according to the lighted label prompt in the window.

.jpg)

Real-time display of the current product press-fitting curve, accurate analysis of data, refined production

.jpg)

1. Displacement repetition accuracy of 0.01mm

2. Displacement repetition accuracy of 0.01mm

3. Maximum 100mm/s unloaded, minimum 0.01mm/s press-fit

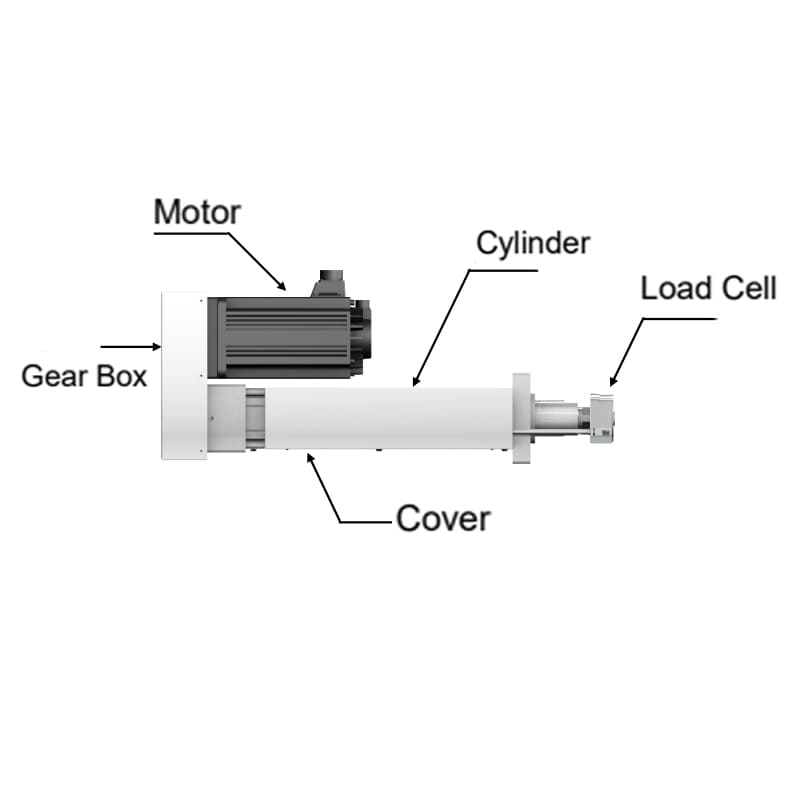

Control servo motors in three ways: position, speed, and torque to realize high-precision positioning of the drive system.

Servo press Functional features

All parameters can be customized, making the servo press mechanism more suitable for the process you need

Human machine interface touch screen control

- 1. The displacement repetition accuracy is 0.01mm.

- 2. The pressure repetition accuracy is 1% F.S.

- 3. Single stroke six stages speed with precision press fitting.

- 4. Online press fitting can judge the quality of products.

- 5. The pressing process is displayed in real time in the form of curve.

- 6. Three press fit modes are available.

- 7. 100 sets of press fitting procedures can be set.

- 8. Press fit data can be stored and extracted.

Single stroke six stages speed

- 1. Fast forward: approaching the workpiece quickly.

- 2. Control test: testing from no-load to load.

- 3. Press fit: workpiece press in.

- 4. Buffer: decelerate before the end of press fitting.

- 5. Pressure maintaining: press fitting end position stays.

- 6. Return: return to work origin quickly.

Three press fit modes can be selected during program setting

- 1. Constant press fitting speed, set precise position and stop.

- 2. Constant press fitting speed, set precise pressure and stop.

- 3. Constant press fitting speed, set accurate displacement and stop.

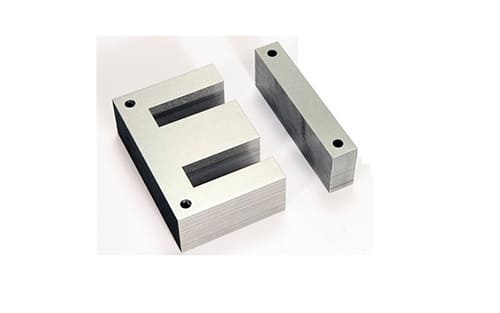

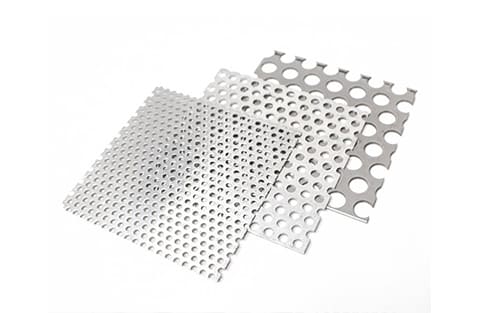

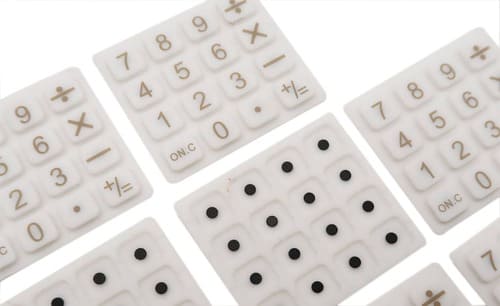

servo press uses

The servo press can complete more processes

It is used for punching, stamping, forming, shallow stretching, shaping and pressure assembly of metal or non-metal parts, blanking of plastic plates, pressing of powder products, etc.

Free sampling and pressure testing for customers

Tailored for each enterprise's process production

Specialized design solutions

Our professional team will design reasonable supporting mechanical solutions according to your needs

View our company

This is our own factory. There is no middleman to earn the price difference !

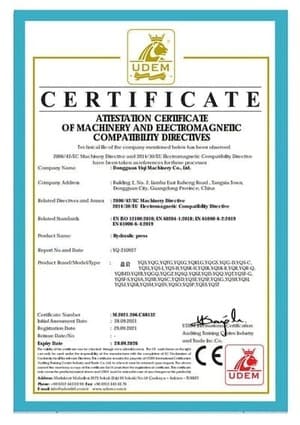

Certificate

It’s time to expect more.

You can inform us in advance of the certificates required by the local machinery and equipment, and we will provide various types of true and valid certificates in the fastest way

Contact Us

main office

Building 21, No. 26 Xinglong Street, Tangxia Town, Dongguan City, Guangdong Province

Phone

+86 18002922652

yqjxmvp168@163.com

Welcome to consult

servo press manufacturers

No matter what type of servo press you need, based on our rich experience, we can provide the most suitable scheme and design for the industry.

About Us

Servo press manufacturers

An excellent team of engineers provides free design, as well as free product sample testing and evaluation

Example of servo press operation.

How it works

“Benefit from our efficient production process with a turnaround time of 15-25 working days, encompassing design, production, installation, and meticulous testing of over 5000 cycle actions. Each unit undergoes rigorous inspection to ensure optimal performance before shipment. Trust in our commitment to quality and reliability for your manufacturing needs.”

Confirm customer requirements and produce a design draft for confirmation

15-25 working days, used for design, production, installation, debugging, repeated testing of 5000+cycle actions, strict inspection before shipment.

Guaranteed quality and speedy delivery

This is our shipping package, sponge protection hydraulic machinery and equipment, export wooden box packaging

Testimonial

What they say about us

Our tenet is to have the best product, best price and

best delivery time to satisfy all our clients

Servo press machine manufacturers

Established servo press factories typically have a wide range of models to meet the needs of different applications and industries. They can handle custom orders, high-volume production, and special requests, making them an ideal partner for companies seeking reliable, consistent machine building solutions.

Why Choose Us

Let us change the way you think about technology

Presses are versatile and commonly used in fabrication shops.

We have rich experience and sufficient confidence to make machines that meet customer requirements.

Professional team with mature technical service support.

To provide design, pre-sales and transportation logistics and distribution service.

Devise a new machine

Types of hydraulic press

Hydraulic presses can be designed as desktop hydraulic presses, C-frame hydraulic presses, four column hydraulic presses(4 Post Hydraulic Press), servo hydraulic presses, hot press machines, etc. All parameters can be flexibly customized.

We will contact you within 1 business day and ensure that your company’s privacy is secure.