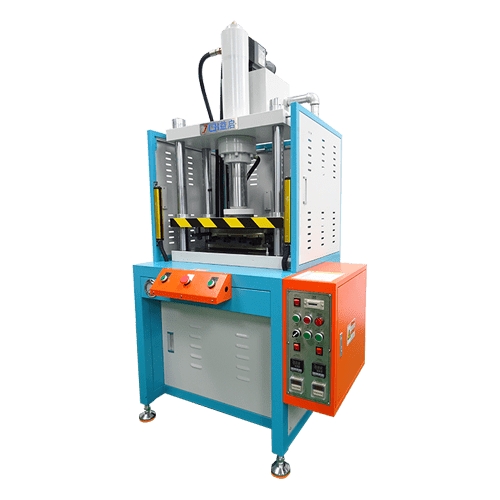

Sponge swab forming machine

Sponge swab forming machine manufacturer

Sponge swab molding technology

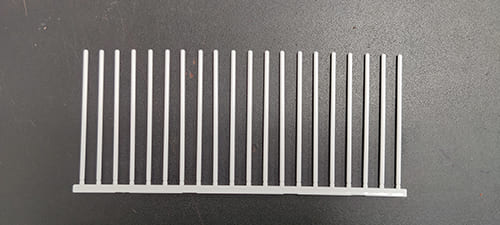

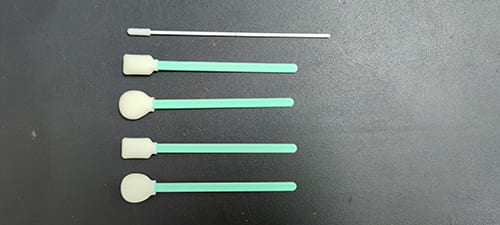

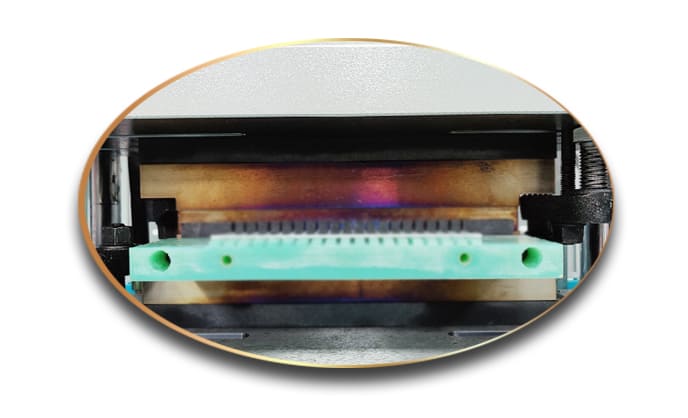

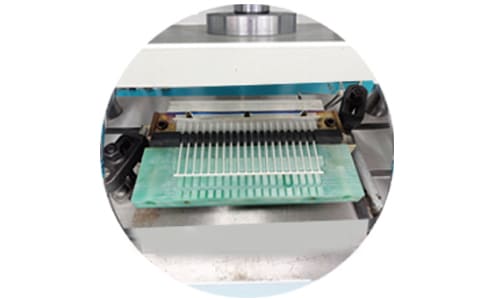

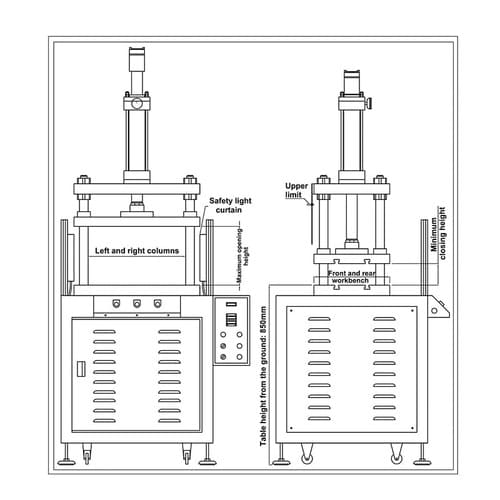

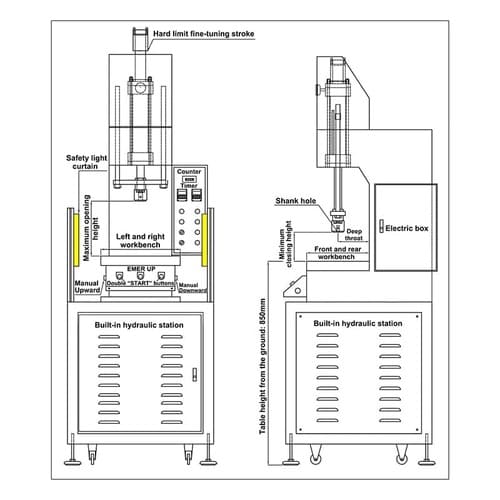

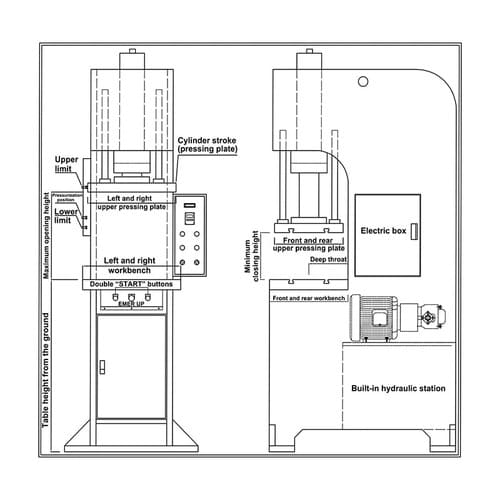

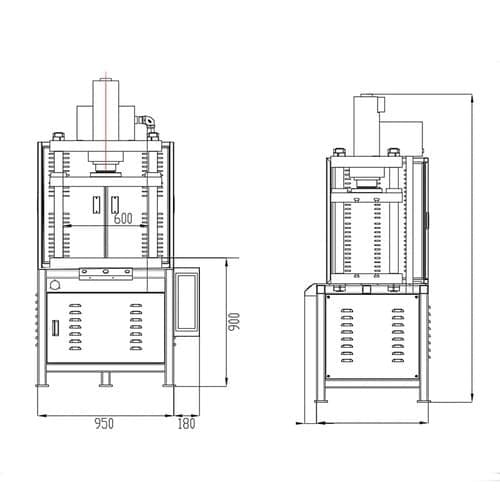

The PP bar is molded by the injection molding machine.The sponge swab is formed by hot pressing and laminating of the sponge swab molding machine. After the completion of mass production, materials can be taken, disinfected, and packaged independently. Sponge swab forming machine is a hydraulically powered machine,which is still based on Pascal’s law. The machine has hot pressing function. It can make different sponge bars according to different specifications of molds.

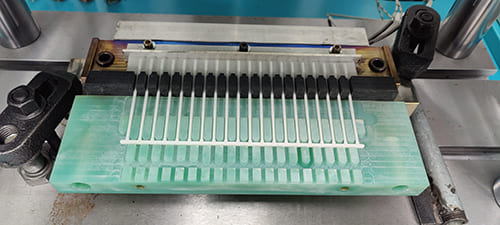

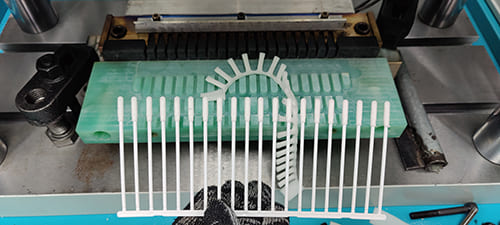

Sponge swab forming machine Quick overview of the hot pressing process

Throat Swab Forming Machine/Sponge Swab Stick Making Machine/Swab Stick Machine/

Medical Cotton Swab Making Machine/Cotton Swab Forming Machine/Medical Cotton Throat Swab Machine/Medical Nucleic Acid Swab Making Machine

.jpg)

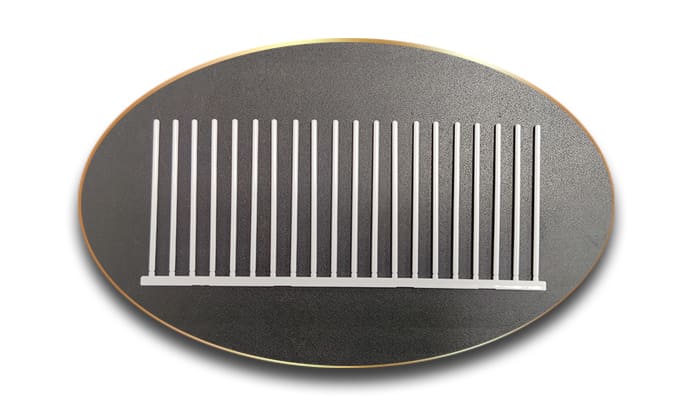

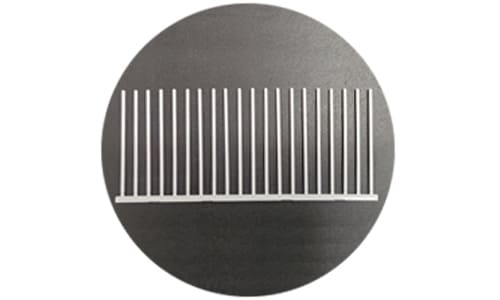

Sponge swab forming machine can customize mold

The mold can be customized according to the specifications of sponge swabs and the number of mold press fit.

The sponge swab forming machine can freely change the mold to produce sponge swabs of different specifications

The sponge swab forming machine can freely adjust the pressure, match the two hand start button and the emergency rise button, and the infrared safety grating protection device.

.jpg)

Sponge swab forming machine Video

Sponge swab forming machine

Press fitting process of sponge swab forming machine

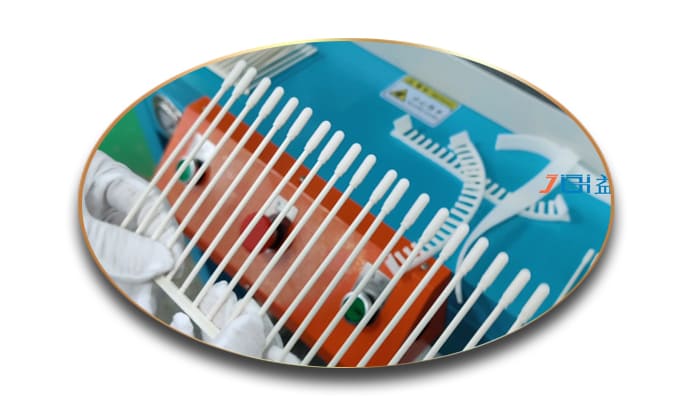

1. stores reserve

2. place

3. Press fit

4. forming

Shape size

quantity

accessory project

General Hot Selling Products

We have more styles, thanks to the fact that we can customize various models, which will be flexibly applicable to more scenarios

It can realize punching, stamping, forming, die cutting, stamping blanking of metal or non-metal parts and powder product pressing.

C-Frame Presses

It can realize punching, stamping, forming, die cutting, stamping blanking of metal or non-metal parts and powder product pressing.

Floor hydraulic press

It can realize punching, stamping, forming, die cutting, stamping blanking of metal or non-metal parts and powder product pressing.

Fast 4 post hydraulic press

It can realize punching, stamping, forming, die cutting, stamping blanking of metal or non-metal parts and powder product pressing.

C Frame

Floor Type

Hot press

Floor Type

Shield type

fast Speed

HOB Cylinder

hot press

Sliding table Type

numerical control

horizontal Type

pressing Plate Type

Customization of humanized parameters and functions

If you don’t know what model you need, please contact us and we will provide you with the most suitable solution

- Pressure adjustable

- Time adjustable

- Position adjustable

- Table size can be ordered

- High quality electrical accessories

- Functions can be customized

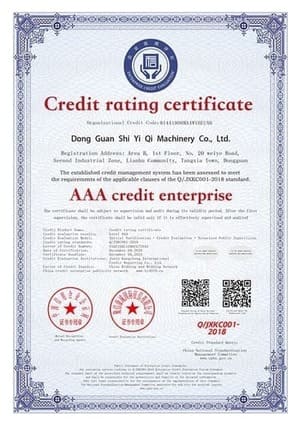

Dongguan Yiqi Machinery Co., Ltd

This is our own factory. There is no middleman to earn the price difference !

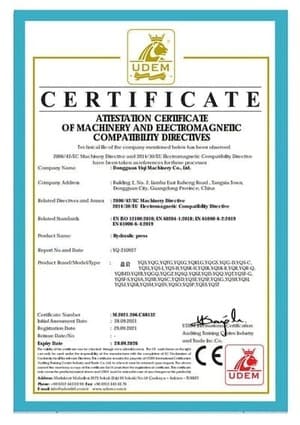

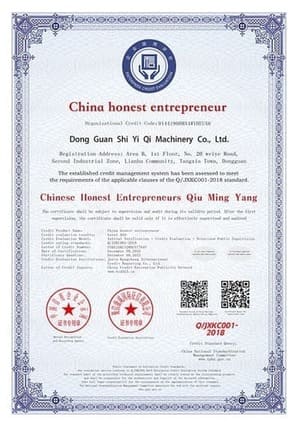

Certificate

It’s time to expect more.

You can inform us in advance of the certificates required by the local machinery and equipment, and we will provide various types of true and valid certificates in the fastest way

Contact Us

main office

No. 20, Weiye Road, The Second Industrial Zone, Lianhu Community, Tangxia Town, Dongguan City

Telephone

+86 18002922652

yqjxmvp168@163.com

contact us

No matter what type of hydraulic press you need, based on our rich experience, we can provide the most suitable scheme and design for the industry.

The delivery is normally completed within 15-25 working days

testimonial

our services has been proven by many client.