Selection guide of hydraulic press

Three elements of hydraulic press purchase

Tonnage (ton), workbench size, machine opening and closing height and hydraulic cylinder stroke.

Tonnage (ton):First of all, we need to determine the tonnage required for the purchase of hydraulic presses. Among our common small hydraulic presses, we have several specifications: 1Ton, 3Ton, 5Ton, 10Ton, 15Ton, 20Ton, 25Ton, 30Ton, 40Ton, 50Ton, 60Ton, 80Ton, 100Ton. To determine the production process, materials and specifications, the general choice will keep the margin, that is, when 10ton is required for processing the workpiece, we suggest to choose 15TON or 20ton machines to meet different needs.

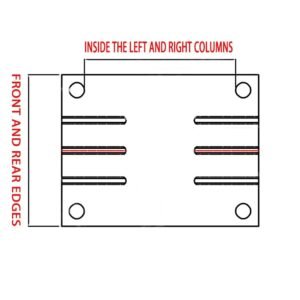

workbench size: we generally have conventional parameter configuration. When the conventional parameter configuration is not suitable, we will provide customized services to make our machine suitable for your production needs. The size of the workbench is usually calculated according to the effective area. The workbench generally has plane, slotting, threaded hole, blanking port and other methods.

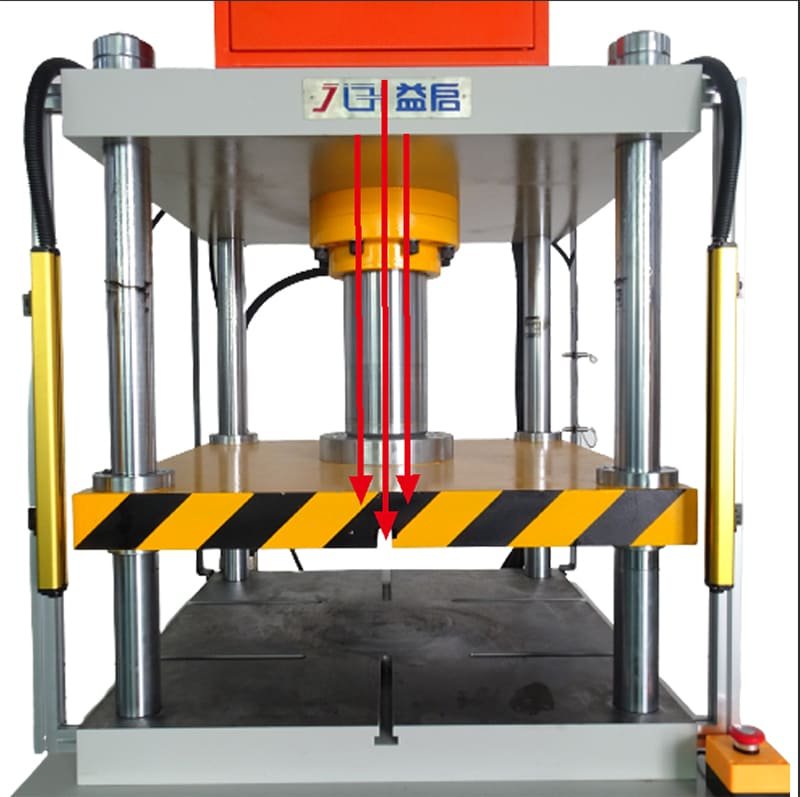

machine opening and closing height and hydraulic cylinder stroke:The opening and closing height of the hydraulic press and the stroke of the hydraulic cylinder: the machine generally designs the opening height according to the tooling die. When the conventional parameter configuration is not enough, a slightly larger opening height can be customized to meet the needs of the tooling die. The stroke of the hydraulic cylinder determines the displacement distance, and the minimum state is complete closure. The closing height is usually based on the clamping height of the die.

Opening height

Hydraulic cylinder stroke

In special cases, customized functions can be realized, such as pressure maintaining, heating workbench, digital display, pressure sensor, warning light, etc.